You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

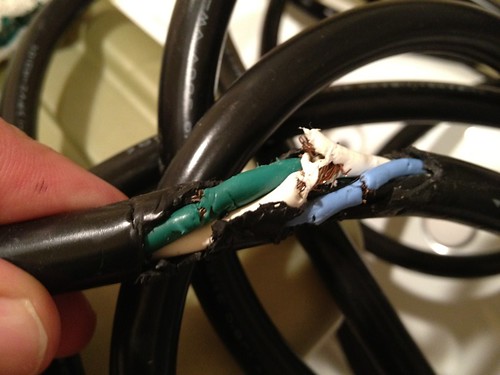

Appreciate your help.--Damaged Charging cable

- Thread starter gpsnut

- Start date

Help Support My Nissan Leaf Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MrIanB

Well-known member

Ingineer with evse upgrade may be able to help you. did you run over it with car or something??

Good luck,

Ian B

Good luck,

Ian B

Stoaty

Well-known member

Yes, and he described the experience as "electrifying". :lol:camasleaf said:Is the dog OK?

adric22

Well-known member

If it were mine.. I'd chop the bad area off the cable, then solder the wires together and use some really good heat-shrink. I assume from the appearance of the cable that this is the regular 120V EVSE... if so, the amperage is much lower than a level-2 and I suspect it would be fine.

jkirkebo

Well-known member

gpsnut said:Thanks for quick replies.

Portable unit.

Beagle ok.

Any link for the "

Ingineer with evse upgrade "

Evseupgrade.com

I'm sure they can repair the cable for you, and also upgrade your unit to 240V operation at the same time if you need that.

mitch672

Well-known member

There are 5 wires in the cable (3, #12's, and 2 smaller ones, perhaps #18awg for Pilot and Proximity), you could just cut it at the damage, and get a standard electric plastic junction box, then connect the wires together with wire nuts, in the box... its simple, and cheap. a more permanent (and expensive) way to fix it, is to strip it back, get some "heat shrink tubing" (of the proper size), solder the correct wire colors back together, then put a giant piece of heat shrink around the whole thing. You could also buy that 12Awg J-1772 cable, but it will be several dollars per foot, and then replace it on both ends, the last solution is the most expensive, and I if fido gets into the cable again, it could be damaged again of course.

davewill

Well-known member

I assume you also intended that he put shrink tubing around each soldered wire (you didn't quite say it). Just out of curiosity, what would you suggest if someone wanted to end up with a weatherproof result (and didn't want to replace the entire cable)?mitch672 said:There are 5 wires in the cable (3, #12's, and 2 smaller ones, perhaps #18awg for Pilot and Proximity), you could just cut it at the damage, and get a standard electric plastic junction box, then connect the wires together with wire nuts, in the box... its simple, and cheap. a more permanent (and expensive) way to fix it, is to strip it back, get some "heat shrink tubing" (of the proper size), solder the correct wire colors back together, then put a giant piece of heat shrink around the whole thing. You could also buy that 12Awg J-1772 cable, but it will be several dollars per foot, and then replace it on both ends, the last solution is the most expensive, and I if fido gets into the cable again, it could be damaged again of course.

TomT

Well-known member

If you cut out the bad section and then put a large adhesive/sealant heat shrink around the outer jacket first, you could inter-wrap, solder and heat shrink all the individual conductors first and then slide the large heat shrink over the conductors, overlapping both sections, and shrink that down on top. They would give you a fairly strong and waterproof repair. I would also be inclined to add some of the nylon contraction weave over the finished product (again you would have it slide it on one end first before anything else) for added strength and support. I'd have no qualms about using it forever that way.

davewill said:I assume you also intended that he put shrink tubing around each soldered wire (you didn't quite say it). Just out of curiosity, what would you suggest if someone wanted to end up with a weatherproof result (and didn't want to replace the entire cable)?

Herm

Well-known member

use a marine grade heatshrink, it has a goop that melts and seals the joint.

TomT

Well-known member

Yep, you can get it at West Marine. I use it on my boat.

Herm said:use a marine grade heatshrink, it has a goop that melts and seals the joint.

smkettner

Well-known member

NEC will frown on soldering wires. Go with a crimp and heat shrink.adric22 said:If it were mine.. I'd chop the bad area off the cable, then solder the wires together and use some really good heat-shrink. I assume from the appearance of the cable that this is the regular 120V EVSE... if so, the amperage is much lower than a level-2 and I suspect it would be fine.

adric22 said:If it were mine.. I'd chop the bad area off the cable, then solder the wires together and use some really good heat-shrink. I assume from the appearance of the cable that this is the regular 120V EVSE... if so, the amperage is much lower than a level-2 and I suspect it would be fine.

Really? How come? Because the solder can potentially melt?smkettner said:NEC will frown on soldering wires. Go with a crimp and heat shrink.

If it was me, I'd prob use solder, not to provide conductivity, but more as a way to ensure two stripped-and-twisted-together conductor remain in good contact. And I second the approach of heat shrink tubing for each conductor and one big shrink tubing over everything. The marine grade heat shrink tubing is new to me; sounds like a good idea too. Finally nater's approach is probably best if you don't have to give up too much length...

Ingineer

Well-known member

You never ever want to use solder on and cables or wires that are subject to flex. This is also true for any cables/wiring used in environments subject to vibration, such as vehicles. The solder and wire strands become a solid mass and right where the solder ends, the strands are subjected to high stress concentration and rapidly break from fatigue even with only a little bit of flex or vibration. There is no safe and reliable way to splice cable that's subject to high flexing unless it's encased in some type of rigid housing with strain reliefs taking the cable tensile load.

You can either shorten the cable if the damaged area is near the ends, or replace it, but splices are forbidden.

We can perform safe and reliable service for this problem. We routinely replace EVSE cords and upgrade lengths for our customers.

-Phil

You can either shorten the cable if the damaged area is near the ends, or replace it, but splices are forbidden.

We can perform safe and reliable service for this problem. We routinely replace EVSE cords and upgrade lengths for our customers.

-Phil

Nekota

Well-known member

If you are in need of a quick repair, a splice with strain relief using butt connectors and a crimping tool for the individual wires and a section of flexible outdoor conduit around the butt splices ( 6" to 8" ) to provide strain relief. If you need water proofing that adds another level of difficulty -- Look at 3M's Splices PDF for some ideas on sealing. http://multimedia.3m.com/mws/mediawebserver?mwsId=SSSSSu7zK1fslxtUnY_vM8_xev7qe17zHvTSevTSeSSSSSS--" onclick="window.open(this.href);return false;

TomT

Well-known member

I'd let Phil repair it and be done with it!

edatoakrun

Well-known member

Ingineer said:You can either shorten the cable if the damaged area is near the ends, or replace it, but splices are forbidden.

-Phil

Phil is correct, IMO, re a permanent repair.

I would also suggest, if you have Phil repair it, you should consider having him upgrade your EVSE to 240 V, if you have not already. I use his 16 A mod for over 90% of all my charging, all of my home charging, and also on the road, at RV parks and residential 240 V outlets.

If you don't want an upgrade, and the shipping time to Phil and back is a problem, you may also be able find a local electrician, capable of making a permanent repair.

I wouldn't have qualms about some of the other methods suggested, as a temporary fix, if it's not convenient for you to have it out of service for a few days, right now. That's what I'd probably do, as I need mine, almost every day.

But you definitely should to get it done right, without any splices, eventually, IMO.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 4

- Views

- 499

- Replies

- 6

- Views

- 419

- Replies

- 16

- Views

- 933