hbquikcomjamesl

Well-known member

- Joined

- Mar 1, 2021

- Messages

- 208

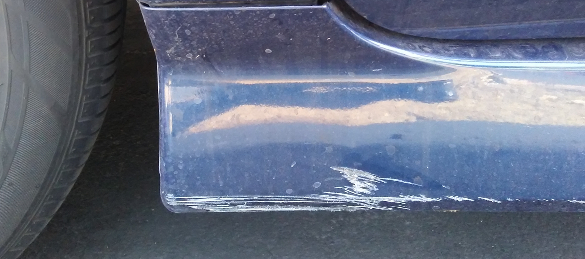

This past Tuesday evening, I put my first significant scratches into my Leaf: I was pulling into my favorite parking space at the Wardlow Blue Line trolley stop (LACMTA), and scraped the plastic side skirting against a protruding bit of curb, just behind the port side front wheel.

scratched skirt by James Lampert, on Flickr

This brings up two questions:

1. What is the best way to fix moderately deep scratches in plastic skirting? I should think that Bondo would be too stiff (and I try to avoid working with polyester thermoset anyway; that stuff is nasty: have you seen the MSDS?)

2. This isn't the first time I've scraped something; I've pulled into a parking space and scraped the concrete wheel-stop. How much work would it be to raise a 2018 Leaf an inch or two?

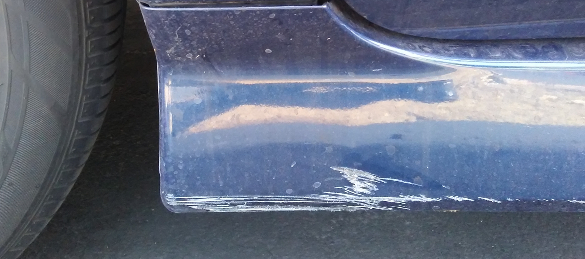

scratched skirt by James Lampert, on Flickr

This brings up two questions:

1. What is the best way to fix moderately deep scratches in plastic skirting? I should think that Bondo would be too stiff (and I try to avoid working with polyester thermoset anyway; that stuff is nasty: have you seen the MSDS?)

2. This isn't the first time I've scraped something; I've pulled into a parking space and scraped the concrete wheel-stop. How much work would it be to raise a 2018 Leaf an inch or two?