You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breaker thrown. I wonder what root source of problem was?

- Thread starter EatsShootsandLeafs

- Start date

Help Support My Nissan Leaf Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

goldbrick

Well-known member

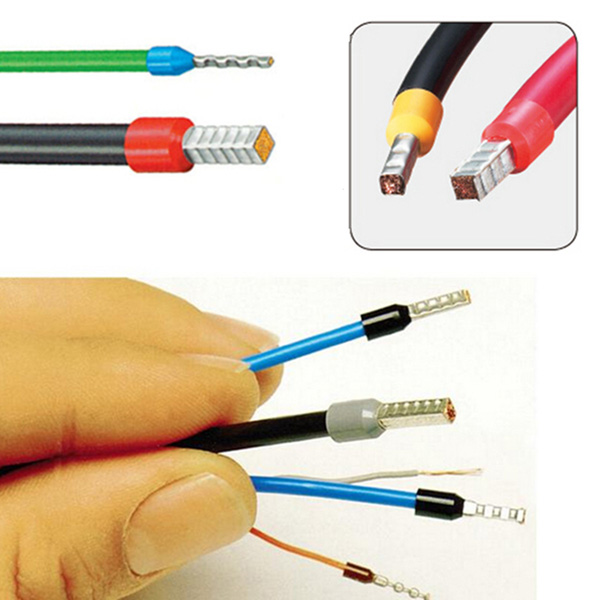

+1 on the Robertson square drive vs a flat blade, you'll be amazed at the difference. If you do it yourself, the wire should be able to go completely through (under) the set screw. You should be able to see the wire peeking out on the far side of the screw. Hold it there while you tighten the screw.

It never hurts to check on the tightness of the connections from time to time but I've read that the newer Al alloys don't have the expansion issues that older Al wiring had so once it's tight, it will probably stay tight. Anti-ox paste is nice but not required. It's also only about $2.

Good luck and be careful.

It never hurts to check on the tightness of the connections from time to time but I've read that the newer Al alloys don't have the expansion issues that older Al wiring had so once it's tight, it will probably stay tight. Anti-ox paste is nice but not required. It's also only about $2.

Good luck and be careful.

If you do have to use a flat blade, make sure that it's large enough for the screw. Most slips & head strips happen because the blade is moving around in the head.

EatsShootsandLeafs

Well-known member

- Joined

- Aug 24, 2012

- Messages

- 716

Update, because I wanted to test a bit more first.

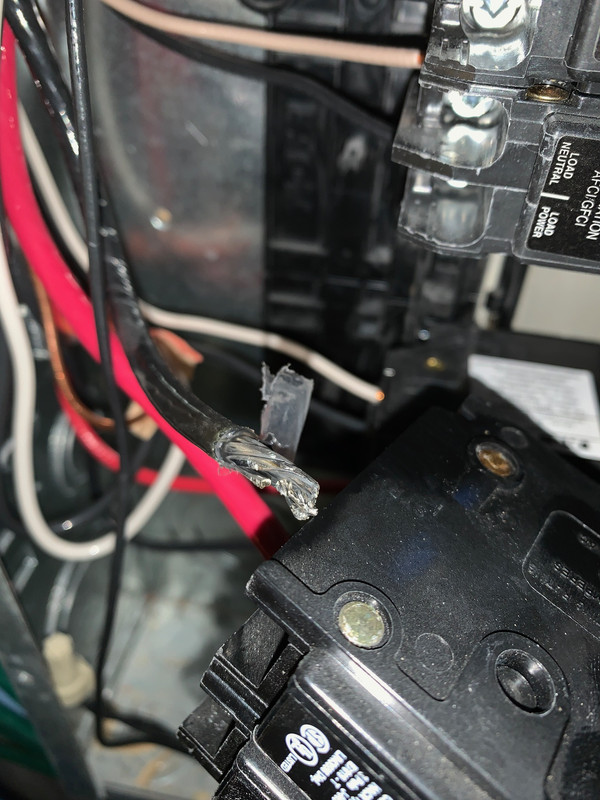

The black wire had not unseated itself, but when I removed it I saw this. A couple of the strands had fallen out/been ruined when the electrician installed it.

Anyway, I snipped off the last 1/4", reattached the wire, and was able to fill 2/3 of the battery on the Leaf yesterday at full amps with the black wire only feeling mildly warm instead of very hot (and it was very hot when I set charger down to 16A, previously). Breaker didn't throw. I will update this thread if this issue recurs but it looks resolved now. Thanks for all the posts!

The black wire had not unseated itself, but when I removed it I saw this. A couple of the strands had fallen out/been ruined when the electrician installed it.

Anyway, I snipped off the last 1/4", reattached the wire, and was able to fill 2/3 of the battery on the Leaf yesterday at full amps with the black wire only feeling mildly warm instead of very hot (and it was very hot when I set charger down to 16A, previously). Breaker didn't throw. I will update this thread if this issue recurs but it looks resolved now. Thanks for all the posts!

I think it threw 3 times, maybe 4. I know it's bad to have them trip too much so I didn't beat on it.How many times have you reset the tripped breaker and continued to use it? If a couple times, the breaker is likely OK to continue using, but if, say, 10 times, it should be replaced by a qualified person.

Similarly, I replaced the burned out spade connector inside my OpenEVSE with a soldered 8 awg spade connector, all is working great at 24 amps (max for my 30 amps breaker).

goldbrick

Well-known member

Glad you caught that and got it fixed. Thanks for the update too, it's nice when there is a logical and conclusive end to this type of problem.

Nubo

Well-known member

goldbrick said:Glad you caught that and got it fixed. Thanks for the update too, it's nice when there is a logical and conclusive end to this type of problem.

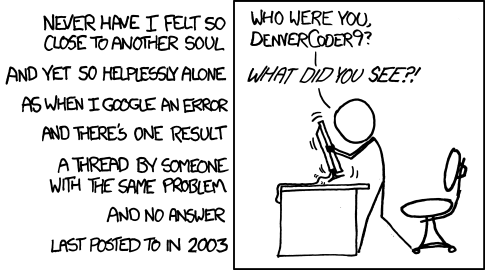

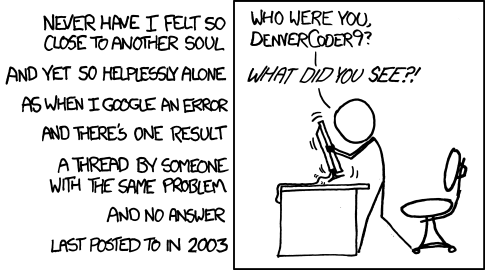

Yep. Googling for answers to technical problems can be challenging sometimes.

EatsShootsandLeafs

Well-known member

- Joined

- Aug 24, 2012

- Messages

- 716

Nubo said:goldbrick said:Glad you caught that and got it fixed. Thanks for the update too, it's nice when there is a logical and conclusive end to this type of problem.

Yep. Googling for answers to technical problems can be challenging sometimes.

So true. I've had this happen more than one when I'm googling a weird error in some code. Invariably the question was from a decade ago and it has answers...but they are wrong.

Off topic since OP's problem is resolved ...

I pretty much know that technical responses in this forum from Whitney or Gerry are the the most valuable, followed by a select few others. Newbs are inundated with noise (or worse) and often flounder since they lack filters. This problem has plagued the internet forever. I still think that karma points are the best solution found so far, even though they sometimes are abused or manipulated.

I pretty much know that technical responses in this forum from Whitney or Gerry are the the most valuable, followed by a select few others. Newbs are inundated with noise (or worse) and often flounder since they lack filters. This problem has plagued the internet forever. I still think that karma points are the best solution found so far, even though they sometimes are abused or manipulated.

As I wrote, you can't always tell the exact nature of a hidden problem just by looking at one photo of it. The electrician obviously used a big pair of linesman's pliers (or something similar) and he crushed that wire in multiple places, to the point of causing part of it to crumble. I wouldn't use that electrician again. I've seen all sorts of serious mistakes in rewiring large parts of my house, but never that one.

Indeed. So much for 'hiring a pro.'LeftieBiker said:I wouldn't use that electrician again.

The use of Alu wire was a fat hint that the electrician was cutting corners. I'm not even sure it would have passed inspection in the USA.

I've come around to the idea of buying the more expensive (but still moderately priced) receptacles for high current applications, mostly so that the terminal is a V shaped pressure fitting at higher torque instead of screw on wire at lower torque. In the US, Bryant and Hubbel are two such vendors. While the topic was on my mind, I went out to my 14-50r to see what my electrician, whom I respect very much, had installed. Thankfully not the Home Depot/Lowes garbage, but an OK but not great Cooper.

I'm going to swap it out for a better receptacle, start with new wire ends, torque to spec and consider it a lesson learned: components have to be specified in the work order.

knightmb

Well-known member

The way the picture looks, the screw was only making contact with half the wire bundle, very unprofessional job by the electrician and they should know better. :shock:

That's amateur hour mistakes, don't hire that electrician again.

That's amateur hour mistakes, don't hire that electrician again.

EatsShootsandLeafs said:Update, because I wanted to test a bit more first.

The black wire had not unseated itself, but when I removed it I saw this. A couple of the strands had fallen out/been ruined when the electrician installed it.

Anyway, I snipped off the last 1/4", reattached the wire, and was able to fill 2/3 of the battery on the Leaf yesterday at full amps with the black wire only feeling mildly warm instead of very hot (and it was very hot when I set charger down to 16A, previously). Breaker didn't throw. I will update this thread if this issue recurs but it looks resolved now. Thanks for all the posts!

I think it threw 3 times, maybe 4. I know it's bad to have them trip too much so I didn't beat on it.How many times have you reset the tripped breaker and continued to use it? If a couple times, the breaker is likely OK to continue using, but if, say, 10 times, it should be replaced by a qualified person.

wwhitney

Well-known member

Nothing wrong with modern aluminum wiring. Problematic aluminum wiring is historical; a different alloy was widely used for 15A and 20A branch circuits during the 70s. That alloy turned out not to work well with standard connections, due to an incompatibility in its coefficient of thermal expansion and connection not designed to handle it (I believe).SageBrush said:The use of Alu wire was a fat hint that the electrician was cutting corners. I'm not even sure it would have passed inspection in the USA.

But the current electrical alloy has eliminated those issues. And aluminum wiring is not being made in sizes appropriate for 15A and 20A branch circuits, so its use is limited to larger circuits, which are typically point to point. As long as the terminations at both end are rated for aluminum, no problem.

Copper beats aluminum in basically only one metric: ampacity (how much current can be safely carried) per unit volume. Aluminum beats copper in ampacity per unit cost and ampacity per unit weight, [By unit here I mean per unit length, so unit volume is just cross sectional area.]

Cheers, Wayne

(My bolding above )wwhitney said:But the current electrical alloy has eliminated those issues. And aluminum wiring is not being made in sizes appropriate for 15A and 20A branch circuits, so its use is limited to larger circuits, which are typically point to point. As long as the terminations at both end are rated for aluminum, no problem.

Good information, thanks.

I highlighted the IF, since an electrician (such as the one here) who does not pay attention to detail might also miss your point.

Question: Are the torque specs the same ? Or does the manufacturer have to give torque specs for each wire type ?

wwhitney

Well-known member

As to the IF, yes it's important to check, but if you do I think you'll have find most/all breakers are rated for aluminum, and most/all large receptacles are. Hardwired equipment may well say in the manual "use copper conductors only" or the like; my EVSE said that. But if the equipment needs a disconnect in front of it, it would be fine to run aluminum to the (aluminum-rated) disconnect and then copper from there to the equipment; that comment in the instructions is just about the terminals. You could also just run aluminum and pigtail to copper with the proper connector (e.g. a Polaris style), although that's a bit of trouble.SageBrush said:I highlighted the IF, since an electrician (such as the one here) who does not pay attention to detail might also miss your point.

Question: Are the torque specs the same ? Or does the manufacturer have to give torque specs for each wire type ?

My experience is not extensive, but the torque specs I've seen do not differentiate between copper and aluminum.

Cheers, Wayne

EatsShootsandLeafs

Well-known member

- Joined

- Aug 24, 2012

- Messages

- 716

I've noticed this on some rare topics over the 20+ years I've been online. Generally speaking one can get a lot of good advice, quickly, on a multitude of topics. But, rarely, some topic will produce weird responses--sometimes from a lot of people. Responses that are inconsistent with what professionals in an industry do.SageBrush said:Off topic since OP's problem is resolved ...

I pretty much know that technical responses in this forum from Whitney or Gerry are the the most valuable, followed by a select few others. Newbs are inundated with noise (or worse) and often flounder since they lack filters. This problem has plagued the internet forever. I still think that karma points are the best solution found so far, even though they sometimes are abused or manipulated.

Examples: I remember when I was doing my basement a lot of people online saying that stud walls need to be essentially on moving pillars so that if the floating slab moves up and down it doesn't shift the house off the foundation. I think they got this idea from who knows where and it just kind of grew like fake news.

Also a surprising number of people on forums think that burying gutter drains should be done not with the PVC specifically made for that (thin, light, cheap) but with schedule 40 heavy duty PVC.

goldbrick

Well-known member

Things vary widely. In my area the soils are expansive and that is how basement walls are framed. It won't pass inspection otherwise and the drywalll will crack. Across the street, a new building is being built. They are drilling 20 ft holes that are filled with concrete. The foundation will be built on top of those pilings. That is a requirement for this soil type but obviously isn't done everywhere.

Reading forums does take some care to separate the wheat from the chaff. The more-professional forums are usually a good source of information but that requires being up to speed on the trade lingo. And sometimes even the pros don't agree. The NEC is contestable and is updated every few years. Things that were kosher on the 20xx code may not be allowed under the 20yy code, etc. I've seen forums where licensed electricians get into a huge pissing contest because they do things differently or interpret the NEC differently.

Reading forums does take some care to separate the wheat from the chaff. The more-professional forums are usually a good source of information but that requires being up to speed on the trade lingo. And sometimes even the pros don't agree. The NEC is contestable and is updated every few years. Things that were kosher on the 20xx code may not be allowed under the 20yy code, etc. I've seen forums where licensed electricians get into a huge pissing contest because they do things differently or interpret the NEC differently.

denwood

Well-known member

I had this same problem with my garage feed when running 16 amps over a 30 amp service charging our LEAF.

The issue was resistance on one leg/fuse of the 220 Volt fuse holder (there are two) at the house panel feeding the garage,...overheating after about 20 minutes. Redoing the connections and cleaning the fuse cartridge holders fixed the issue. Pics etc. here:

https://www.mynissanleaf.com/viewtopic.php?f=27&t=32156

The issue was resistance on one leg/fuse of the 220 Volt fuse holder (there are two) at the house panel feeding the garage,...overheating after about 20 minutes. Redoing the connections and cleaning the fuse cartridge holders fixed the issue. Pics etc. here:

https://www.mynissanleaf.com/viewtopic.php?f=27&t=32156

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 15

- Views

- 5K

- Replies

- 1

- Views

- 10K

- Replies

- 15

- Views

- 1K